There seems to be a trope going around that modern KitchenAid mixers are specifically inferior to vintage ones because their “gears are made of plastic” (or a similarly phrased complaint).

This is categorically not true.

All of the gears in full-sized tilt-head KitchenAid mixers, from a 60s-era K45, the 90s KSM90 “Ultra Power” or the modern KSM150 Artisan (and all the variants in between, but not the Artisan Mini or Accolade), are the same. This is also the same gearing used in the older bowl-lift models: K5A, K5SS, and KSM5/KPM5/KSM50/etc.

“Professional”, “Pro Line”, “Commercial”, and bowl-lift models introduced in 2023 (KSM55, KSM60, KSM70) use all-metal gear trains of varying designs, discussed below.

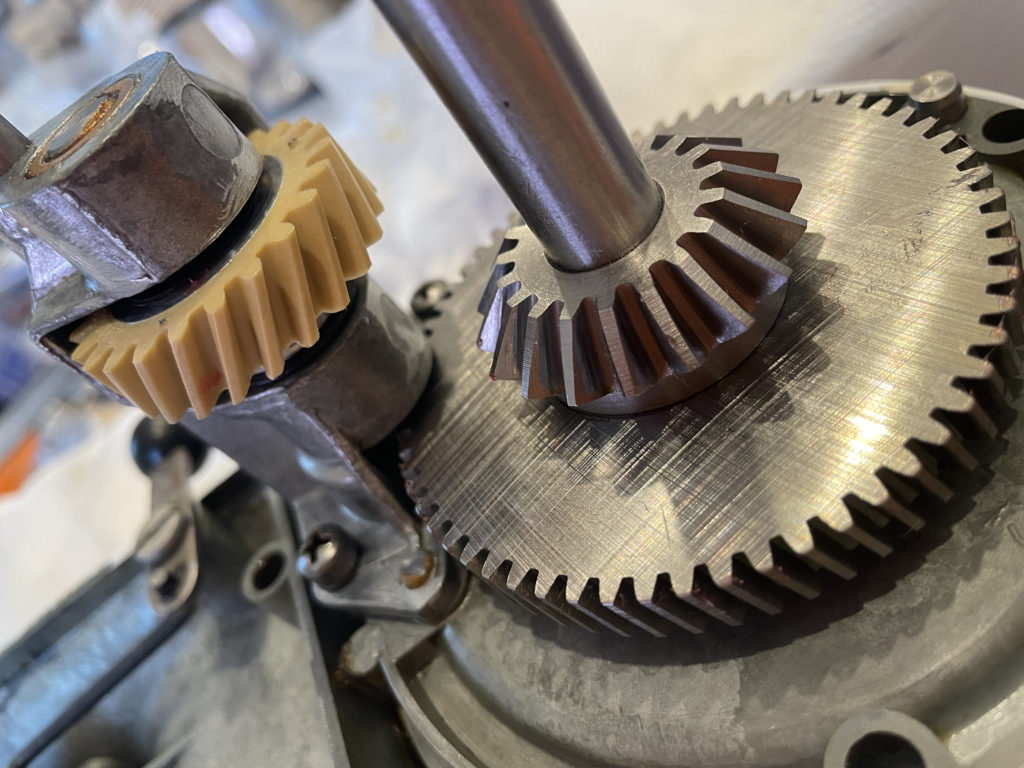

In these mixers, the main gear, accessory hub gear, planetary pinion gear (which makes the beater spin on its axis), planetary ring gear, and the drive pinion gear (which turns the main gear) are all metal. With maintenance and barring accident, they’ll last just about forever.

The worm follower gear is a nonmetallic “sacrificial” gear which is designed to fail and protect the motor (and the other gears) if something jams the beater (or an attachment connected to the drive hub). This has always been the case, although the worm follower gears in very old mixers are made out of a different material.

The gear in the center looks metallic, but isn’t.

In a mixer of sufficient age (or mileage), eventually the teeth on the worm follower will wear down enough that it starts to slip. However, a mixer needs to be very old or very hard used to get to that point. Still, it’s a good reason to inspect the plastic gear whenever you have the machine open for grease service (which you should do every couple of years, or more often if you use the mixer a lot or for heavy work).

In the early days, the metal gears in the drive train were machined from blanks; they’re beautifully crafted shiny bits of metal. At some point in the early 80s (late-series Hobart production) they started using another process which isn’t nearly as nice but has no significant practical effect on the quality or performance of the mixer.

All-Metal Gear Trains

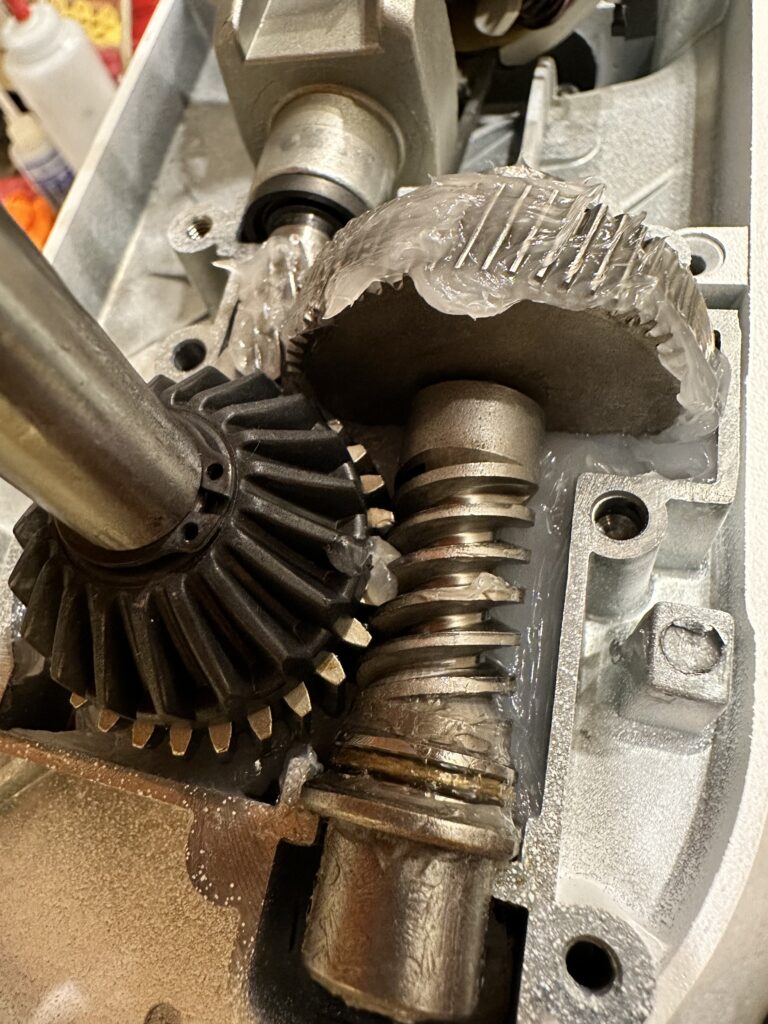

The “Professional HD”, “Professional 5 Plus”, “Professional 6”, and “Professional 600” model types (KG25, KV25, KP26, and a few others) use a different setup, in which the motor is a completely enclosed unit within the body of the mixer, and the motor shaft turns an enclosed transmission. The gears in the transmission are metal as well; and the worm gear follower is made of bronze. This allows the Pro series mixers to handle heavier loads; but the bronze gear is the “mechanical fuse”, and it too will wear and can fail.

(Side note: using a metal worm follower does not make this model type intrinsically any more reliable. These are mechanical things, and with use they will wear and certain things will need repair.)

(Side note 2: early generations of this design used a plastic housing for the transmission, which was prone to failure. After 2005 or so Whirlpool switched to a metal housing for the transmission, but there are many mixers still in service using the original plastic housing. If your mixer has a plastic housing, it’s due for maintenance and at that time you should replace the transmission housing with the upgraded part. You’ll find more details on parts and materials here.)

The “Pro 6000HD”, “Pro Line”, “Commercial” 8-quart, and new bowl-lift models introduced in 2023 (KSM55/KSM60/KSM70) collectively use yet a different gear train design which is (as above) also comprised entirely of metal gears. These models use an integrated motor/transmission assembly which does not employ a “sacrificial” gear. This assembly is not field-serviceable or field-repairable; and there are no maintenance or repair parts available. If the gear train wears out or something in the gear train breaks, the entire drive assembly must be replaced as a single unit. (This is still less costly than a new mixer.)